>Support>Technical library>The key factors for selecting the iron core of transformers

>Support>Technical library>The key factors for selecting the iron core of transformers

The key factors for selecting the iron core of transformers01-29, 2024

Compensation method for high-precision open close current transformers

Many soft magnetic materials can be used as transformer cores, but their usage is not entirely the same, and the resulting transformer performance also varies. There are several main differences.

1. High characteristic

Different soft magnetic materials have different frequency characteristics. Some soft magnetic materials can be applied in the high-frequency field, while others are not suitable for application in the high-frequency field. So, some soft magnetic materials are suitable for making high-frequency transformers, while others are not.

2. Linear characteristics

The linearity of the magnetization curve of different soft magnetic materials varies. Soft magnetic materials with good linearity have better performance consistency under different excitation currents, while soft magnetic materials with poor linearity will have significant differences in performance under different excitation currents. Therefore, some soft magnetic materials are suitable for making transformers that also require high low-end performance, while others are not suitable.

3. Anti saturation ability

The saturation magnetic induction intensity of soft magnetic materials with different anti saturation abilities varies, resulting in some soft magnetic materials having strong anti saturation abilities, while others are easily saturated. So, some soft magnetic materials are suitable for making measuring transformers, while others are suitable for making protective transformers.

4. Weak magnetic field permeability

The magnetic permeability of different soft magnetic materials varies. Some soft magnetic materials still have high permeability under weak magnetic fields, while others have poor magnetic permeability under weak magnetic fields. So, some soft magnetic materials are suitable for detecting zero magnetic flux in the iron core of multi-stage transformers, while others are suitable for bearing the main magnetic flux in the iron core of multi-stage transformers.

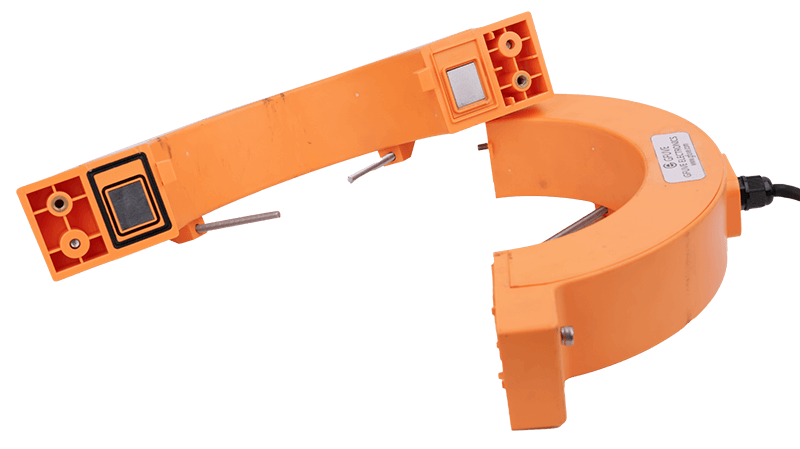

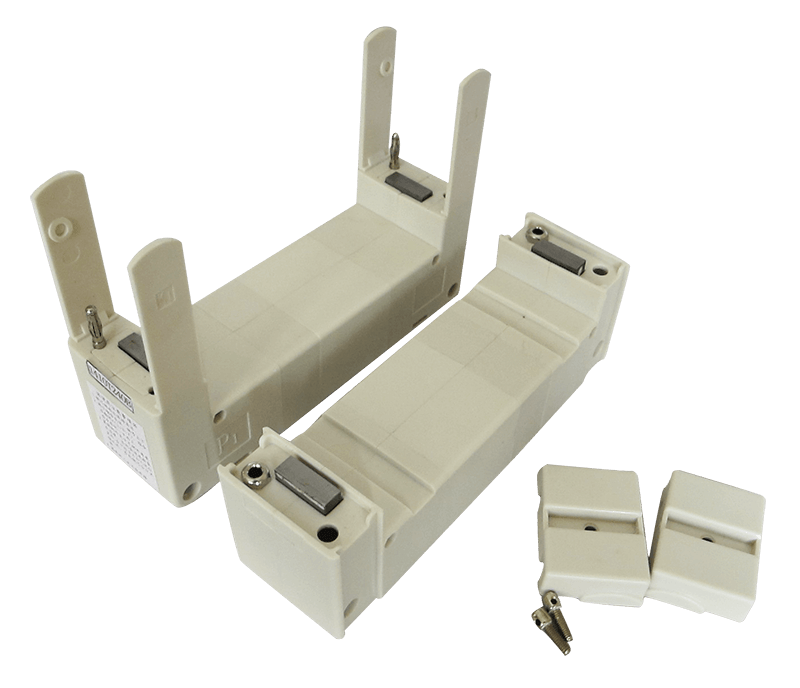

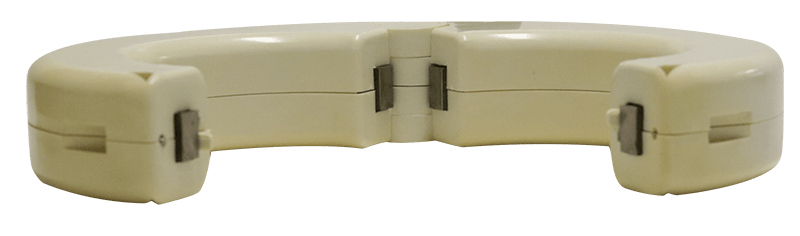

5. Flatness of the cut surface

For closed iron cores made of different soft magnetic materials, when the closed iron core is cut into two parts, their cross-sectional characteristics are different. Some can be processed very smoothly, while others are difficult to process smoothly. In addition, for some soft magnetic materials, the wound iron core may become loose, and these factors affect the performance of the two parts of the iron core after sealing. So, some soft magnetic materials are suitable for making open and close transformers, while others are not suitable.

So, different soft magnetic materials have different applications, it is very important to understand the various characteristics of different soft magnetic materials and provide a basis for the selection of transformer cores!

In summary, the selection of transformer core must be based on the purpose of the transformer and the performance requirements of the transformer, combined with the comprehensive performance of the soft magnetic material, to choose a suitable soft magnetic material as the transformer core. Only in this way can the performance of the soft magnetic material be fully utilized, and the designed transformer have good performance and applicability.

In order to achieve high precision and have an open and close structure for current transformers, soft magnetic materials with high magnetic permeability should be selected as the iron core as much as possible. The cross-section of the iron core should have good smoothness and a certain mechanical strength. At the same time, for current transformers with different structures and compensations, sometimes emphasis is placed on the weak magnetic field permeability, anti saturation ability, or linear characteristics of the iron core. In this case, it is necessary to choose the corresponding iron core to meet the corresponding requirements. In the chapter on the implementation of high-precision open close current transformers, the key elements of transformer core selection will be combined, and suitable soft magnetic materials will be selected as the core according to the specific requirements for achieving high-precision open close current transformers.